Maximize Safety & Efficiency with Dock Restraints

Dock restraints play a critical role in preventing trailer movement during loading and unloading, significantly reducing the risk of accidents and operational disruptions. Designed to secure any trailer to the dock, these systems are essential for maintaining a safe working environment in both industrial and commercial settings. By investing in reliable dock restraints, you can enhance operational efficiency, protect your workers, and ensure smooth logistics processes. Explore our range of solutions tailored to meet the demands of your facility.

Contact us for all your dock restraint needs.

Improve Safety

Dock restraints secure trailers in place, preventing dangerous movement during loading and unloading. This helps reduce the risk of accidents like trailer creep and early departure, two of the most common causes of dock-related injuries.

Minimize Equipment Damage

Unsecured trailers can lead to forklift tip-overs or equipment collisions. Dock restraints keep the trailer stable, protecting your expensive equipment and reducing downtime due to repairs or replacements.

Boost Efficiency

A secure trailer means fewer interruptions during loading and unloading, enhancing productivity. By preventing unexpected trailer movement, dock restraints streamline processes and reduce downtime caused by accidents.

Selecting the Right Dock Restraint for Your Facility

Choosing the right dock restraint system is crucial for safety and operational efficiency. These systems can be equipped with various types of communication tools, including lights and sensors, to ensure safe and clear interaction between dock workers and truck drivers. Below are the main types of dock restraints, broken down by functionality, to help you find the right fit for your industrial or commercial operation.

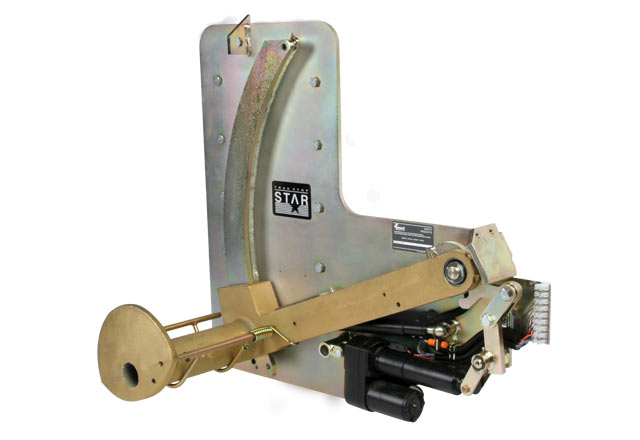

KELLEY – the World’s Leader in Loading Dock Equipment

Premier Warehouse Solutions is proud to offer the full Kelley product in addition to other quality brands. Their innovative solutions include everything from dock levelers and vehicle restraints to controls and HSLV Fans. Take your business to the next level and streamline your operation with Kelley’s unparalleled equipment.